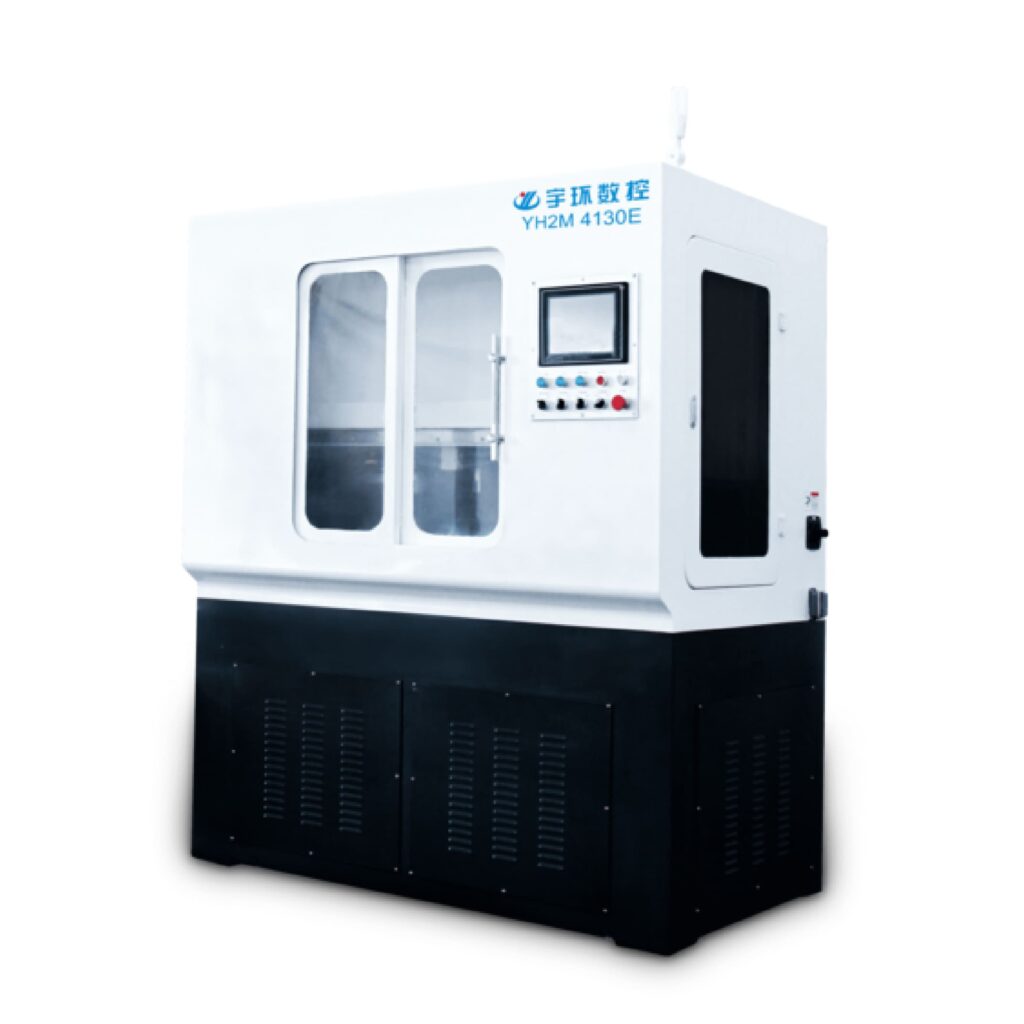

MULTI-EDGE POLISHING MACHINE

MAIN PURPOSE:

This machine is suitable for multi-faceted shaping and polishing of thin sheet parts made of non-metallic hard and brittle materials such as glass and sapphire.

TECHNICAL CHARACTERS:

- This machine is a polishing machine around the workpiece, which adopts the stacking method and the cylinder is pressed tightly.

- The left and right two polishing heads simultaneously perform CNC profiling and polishing on the workpiece, and the lifting motion is used to evenly polish the workpiece up and down.

- Full servo control drive, adopts touch screen + PLC control mode.

SPECIFICATION

| Project | Unit | Parameter |

|---|---|---|

| Polishing head size (outer diameter x height) | mm | φ290*235 |

| Maximum size of workpiece | mm | 300 (diagonal length, and side length ≥ 60) |

| Maximum clamping workpiece thickness | mm | 180 |

| Polishing head speed | rpm | 50-1500 |

| Workpiece rotation speed | rpm | 0.5-3 |

| Polishing head lift speed | mm/min | 5-350 |

| Polishing head motor power | kW | 3 |

| Workpiece rotation motor power | kW | 1.5 |

| Polishing head lift motor power | kW | 0.4 |

| Polishing head moving motor power | kW | 0.4 |

| Number of polishing heads | piece | 2 |

| Total Weight | kg | 2500 |

| Machine tool dimensions (length x width x height) | mm | 1800x1250x2150 |

PROCESSING WORKPIECE

The device can be processed workpiece, including glass, ceramic pieces, sapphire, bearings, valves, carbide inserts, seals, oil pump blades, piston rings, such as: