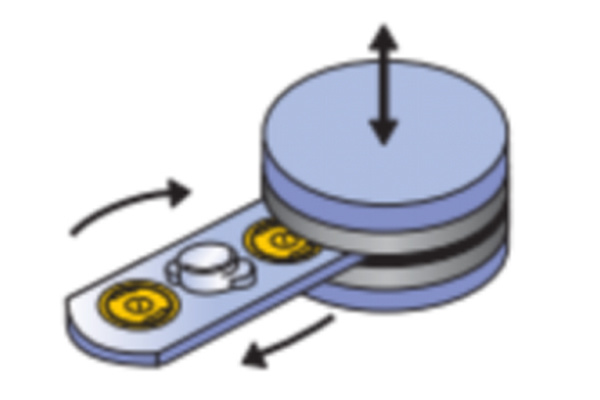

YHMM300B HIGH PRECISION DOUBLE DISC GRINDING MACHINE

MAIN PURPOSE:

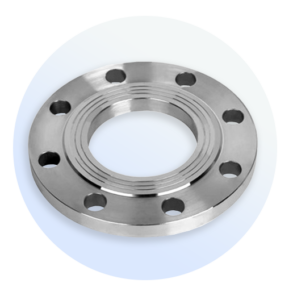

This machine can process all kinds of metal and non-metal thin parts (bearings, valve plates, aluminum alloy plates, seals, oil pump blades, piston rings, etc.) with various shapes and rounds. High-efficiency precision grinding of the upper and lower parallel end faces.

TECHNICAL CHARACTERS:

- The precise and stable grinding angle adjustment technology of the upper grinding head.

- High rigidity and high precision spindle support structure and double nut sliding sleeve technology.

- High-precision feed system design.

- High precision and smooth grinding wheel dressing technology.

- High rigidity feeding mechanism design.

SPECIFICATION

| Item/Product Model | Unit | YHMM300B |

|---|---|---|

| Workpiece diameter | mm | Φ10-Φ80 |

| Workpiece thickness | mm | 8-40 |

| Wheel size | mm | Φ305 |

| Grinding head motor | kw | 7.5 x 2 |

| Grinding head speed | rmp | 50-1000 |

| Feeding tray motor power | kw | 1.5 x 3 |

| Machine quality | kg | 5000 |

| Machine tool dimensions (length x width x height (LxWxH) | mm | 1900x1920x2240 |

PROCESSING METHODS

C mode grinding (C)

Suitable for high-efficiency, multi-specification and variety processing

Continuous grinding (LX)

Suitable for high removal, thin workpieces (1-8mm)

PROCESSING WORKPIECE

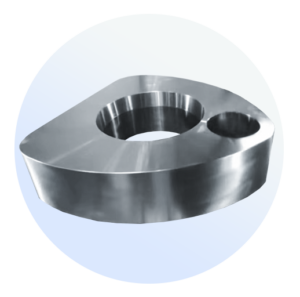

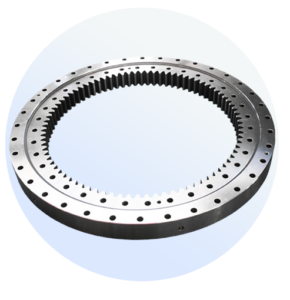

The device can be processed workpiece, including glass, ceramic pieces, sapphire, bearings, valves, carbide inserts, seals, oil pump blades, piston rings, such as: