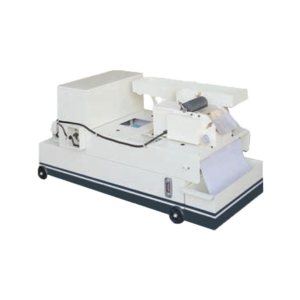

High Precision Surface Grinding Machine - SGS Series

MAIN PURPOSE:

High precision surface grinding machine SGS series is suitable for Die and Mold, Automobile and Heavy Engineering Industry, can be used for steel parts, cast iron, non ferrous metal and non metallic and other large and medium parts grinding.

TECHNICAL CHARACTERS:

- SGS Series Surface grinding machine has robust cast iron and stable structure for precision grinding

- Spindle grinding heads adopts super precision angular contact ball bearing

- Hardened and precision ground vertical lead screw & cross lead screw

- Hydraulic table and saddle movements reversible by proximity switch

- Machine guide ways are accurately hand scraped Automatic continuous lubrication on guideways and lead screws

- The easy to use, conveniently located operator panel includes all buttons and switches.

- The vertical In feed of grinding head is controlled by using the vertical motor for quick rising and lowering in (SHR series) or the servo motor for quick rising and lowering (SHD series), which can also be operated manually.

- Closed hydraulic system is adopted for the reciprocating the work table.

- Transverse movement of cross can be manually feed or the lead screw can be driven by the motor for automatic intermittent feed.

SPECIFICATION

SPECIFICATION / MODEL | Unit | SGS-2050SHR SGS-2050SHD | SGS-2550SHR SGS-2550SHD | SGS-3063SHR SGS-3063SHD | SGS-30100SHR SGS-3010SHD | SGS-4080SHR SGS-4080SHD | SGS-40100SHR SGS-40100SHD | |

|---|---|---|---|---|---|---|---|---|

| Table size (W x L) | mm | 200 x 460 | 250 x 500 | 305 x 635 | 305 x 1020 | 406 x 812 | 406 x 1020 | |

| Max. longitudinal travel | mm | 510 | 560 | 765 | 1130 | 910 | 1130 | |

| Cross travel | mm | 238 | 275 | 340 | 340 | 450 | 450 | |

| Max. distance from spindle center to table | mm | 450 | 450 | 560 | 560 | 560 | 560 | |

| Magnetic chuck size | mm | 200 x 460 | 250 x 500 | 300 x 600 | 300 x 1000 | 400 x 800 | 400 x 1000 | |

| Speed of table longitudinal movement | m/min | 7~23 | ||||||

Table transverse movement | Auto feed | mm/min | 0.1 – 8 | |||||

| Rapid speed | mm/min | 990 | ||||||

| Feed of handwheel | mm/div. | 0.02 | ||||||

Wheel Head Vertical Movement | Auto feed | mm/stroke | ( SHR mode ) 0.005/0.01/0.02/0.03/0.04/0.05 ( Only for SHD model ) | |||||

| Rapid speed | mm/min | 460 | ||||||

| Feed of handwheel | mm/div. | 0.005 | ||||||

Grinding wheel | Speed | rpm | 2850 (50Hz) | 1450 (50Hz) | ||||

| (OD x W x ID) Size | mm | 200 x 20 x 31.75 | 350 x 40 x 127 | |||||

| Spindle Motor | kW | 1,5 | 2.2 | 5.5 | ||||

| Hydraulic Motor | kW | 1.5 | 0.75 | 2.2 | ||||

| Coolant pump motor | kW | 0.04 | 0.125 | |||||

| Vertical elevation Motor | kW | ( 0.25 SHR mode ) ( 0.5 SHD Mode, servo motor ) | ||||||

| Cross feed motor | kW | 0.08 | ||||||

Max loading capacity of the table include magnetic chuck | kg | 120 | 180 | 270 | 400 | 500 | 600 | |

| Total rated power | kw | 3 | 3.7 | 9 | ||||

| Height of machine | mm | 1675 | 1890 | |||||

| Floor space (L x W) | mm | 1700 x 1200 | 2300 x 1650 | 2900 x 2200 | 4400 x 2200 | 3600 x 2400 | 4400 x 2400 | |

| Gross weight | kg | 1200 | 1800 | 2600 | 3300 | 3500 | 4000 | |

| Packing dimensions (L x W x H) | mm | 1900 x 1720 x 2175 | 2000 x 2100 x 2175 | 2350 x 2220 x 2150 | 2950 x 2220 x 2210 | 2850 x 2270 x 2180 | 2950 x 2270 x 2210 | |

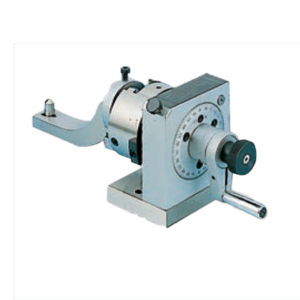

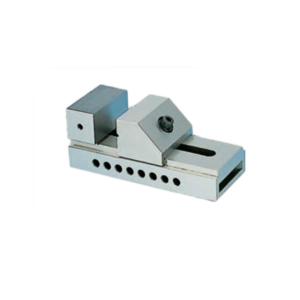

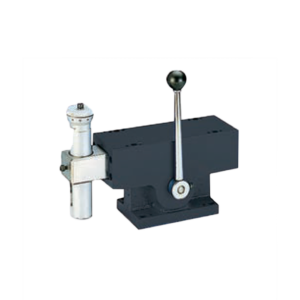

Optional Accessories