HIGH PRECISION VERTICAL DOUBLE DISC SURFACE GRINDING MACHINE

We designed for high precision grinding of the two paralell surfaces of flat metallic parts such as bearing, valve plate, carbide chip, seal, oil pump vane, piston ring, etc. It can also grind the flat surfaces of non-metallic parts of hard & brittle materials like glass and ceramics. The uniquely sophisticated & compact design of the machine ensures high precision & efficiency. High precision Yuhuan Double Disc Surface Grinding has been recognized by the market as one of the most practical grinding solution for mass production of flat parts.

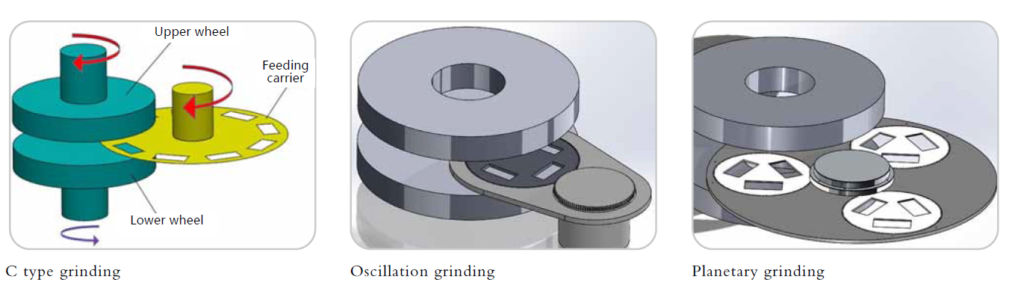

GRINDING METHOD

| MODEL | GRINDING METHOD | TOOL Φ | WORKPIECE Φ |

|---|---|---|---|

| YHDM580CNC/CBN | C type/Oscillation/Planetary | 585 mm | 120/280mm |

| YHDM580B | C type/Oscillation/Planetary | 585 mm | 120/280mm |

| YHDM750A | C type/Oscillation/Planetary | 750 mm | 180/320mm |

| YHMM7758 | C type/Oscillation/Planetary | 585 mm | 120/280mm |

GRINDING METHOD

TOOL SYSTEMS

CASE REFERENCES

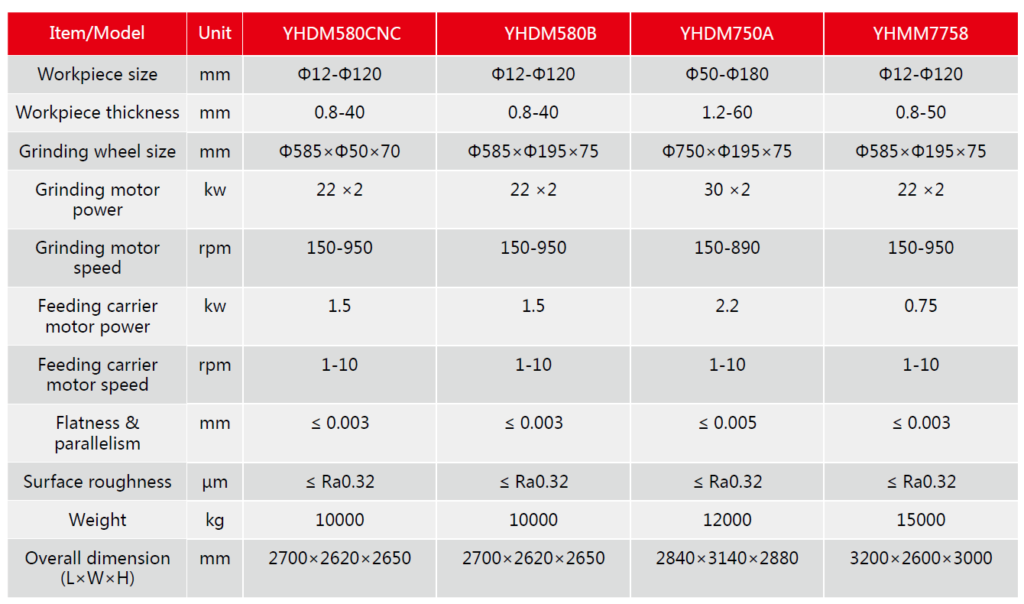

LIST OF SPECIFICATIONS

MACHINERY PRECISION & STABILITY

INSTALLATION OF GRINDING WHEEL

Integrated crane is equipped for unloading/loading of the abrasive wheels. Unique swing-out structure for the feeding carrier provides outstanding space for tool changes. Portable wheel changing aid for rapid & easy transportation of the tools, reducing labor intensity and improving work efficiency.

TOOL DRESSING

We adopt oscillating dressing for the dressing unit. The swing arm is fixed by the revolving shaft with step less speed regulating. The fixture for the sharpening unit can be dismounted easily, and upper & lower grinding wheels can be dressed at the same time. Hydraulic control circuit of the wheel dressing is controlled by hydraulic lock..

FEEDING CARRIER CHANGE

Customized carriers available for all types of workpieces, exch angeable in 2 min.

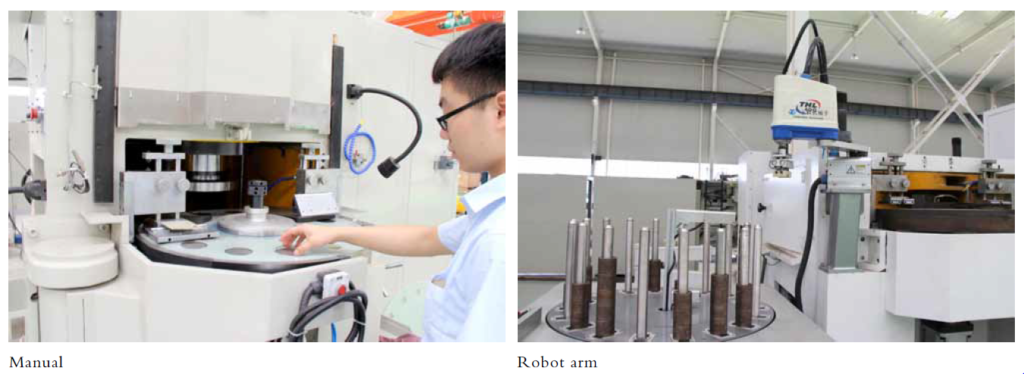

WORKPIECE LOADING