DOUBLE SIDE FINE GRINDING MACHINE

Main Purpose:

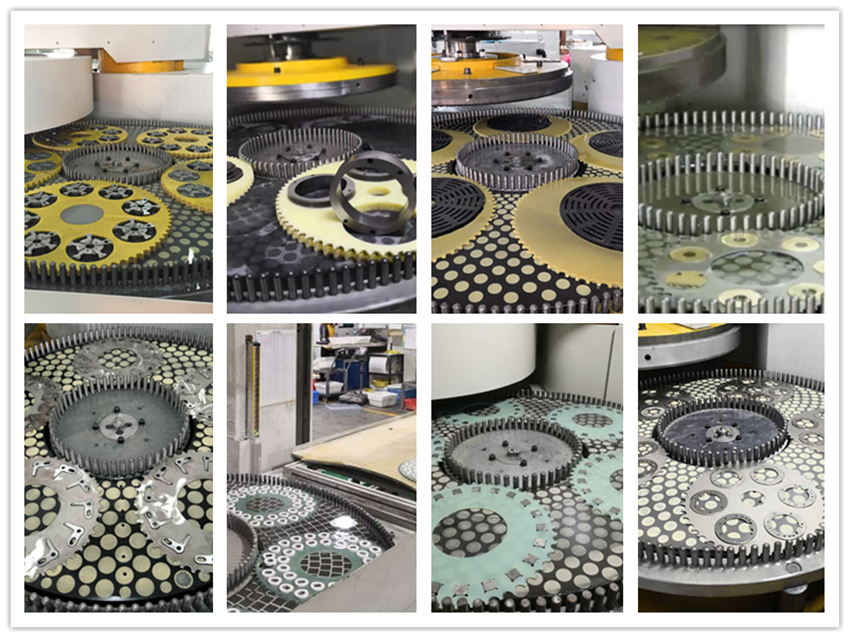

Double side fine grinding machine is an automatic high-efficiency machine that is suitable for batch processing of parts. It can achieve 0.002mm flatness & parallelism and surface finish up to 0.1 Ra. It is widely used for grinding and polishing the surface of parts, using CBN grinding wheels, diamond grinding wheels, diamond grinding pads to achieve efficiently and accurately double-surface grinding and thin processing for metal and non-metallic hard & brittle materials such as hydraulic and pneumatic components, automobile fuel pump components, refrigeration compressor components, oil pump components, engine components, seals, piston rings, measuring tools, carbide blades, ceramic valve, cutting tools, magnetic materials and other products.

TECHNICAL CHARACTERS:

- High strength cast iron machine body

- Three independent adjustable driving motors are applied to upper disc, lower disc and inner ring

- Upper working disc can be manually or automatically swing out

- Pneumatic control

- Digital size control system

- Inner ring rotates under servo driving

- Semi-automatically loading and unloading device can be configured

- Constant temperature cooling and filtering system

- Touch screen control interface

- Compressed protection for upper working disc

- Strong fault diagnosisfunction

- Aplurality of functions for selection

- No or less maintenance, simple and convenient operation Customized processing solution, to improve product capacity

SPECIFICATION

| Item/Model | Unit | YHM530 | YHM720 | YHM1000 | YHM1200 |

|---|---|---|---|---|---|

| Diameter of Grinding Wheel | mm | Φ530 | Φ720 | Φ1000 | Φ1200 |

| No. of Carriers | nos. | 5 | 6 | 6 | 6 |

| Workpiece Range (Max.) | mm | Φ150 | Φ200 | Φ300 | Φ400 |

| Thickness of Workpiece (Max.) | mm | 30 | 40 | 100 | 100 |

| Speed of Upper & Lower Wheel (Max.) | rpm | 105 | 105 | 80 | 85 |

| Speed of Inner Ring (Max.) | rpm | 65 | 75 | 65 | 65 |

| Spindle Power of Upper & Lower | kw | 2 x 4 | 2 x 5.5 | 2 x 9.2 | 2 x 11 |

| Power of Inner Ring Servo Motor | kw | 2 | 2 | 3 | 5 |

| Max Pressure | kgf | 600 | 700 | 1000 | 1500 |

| Electrical Connection | – | 415 Volt, 3 Phase, 50 Hz | 415 Volt, 3 Phase, 50 Hz | 415 Volt, 3 Phase, 50 Hz | 415 Volt, 3 Phase, 50 Hz |

| Weight | kg | 3000 | 4500 | 6000 | 6500 |

| Overall Dimension (L × W × H) | mm | 1500 x 1700 x 2500 | 1800 x 1900 x 2500 | 2500 x 2100 x 2700 | 2600 x 3000 x 2300 |

FINE GRINDING PROCESS

High precision surface grinding or fine grinding is a super finishing process performed by removing material from two surfaces of a component resulting in extremely precise geometric accuracy and surface finish. Typically, it is the last grinding step of a mechanical production chain utilized to improve and/or correct the geometry of parts coming from sintering, sawing, molding or similar operations. Depending on the application, the stock removal also can be taken from just one surface.

When the machine is working, upper and lower grinding discs as well as the planet wheel rotate simultaneously to drive work pieces to do reciprocating planet motion between the two grinding plates. Various grinding materials such as super hard abrasive: Diamond grinding plates, CBN(cubic boron nitride) grinding plates; Conventional abrasives: Cast iron plates, GC plates, etc can be adopted for different requirements of various products, so as to achieve double side precision grinding on work pieces made from various materials. Our equipment take advanced probe side measurement and Sony size measuring controller to realize real-time online measurement control on processed work pieces.

COMPONENTS DURING FINE GRINDING PROCESS

COMPONENTS DURING FINE GRINDING PROCESS