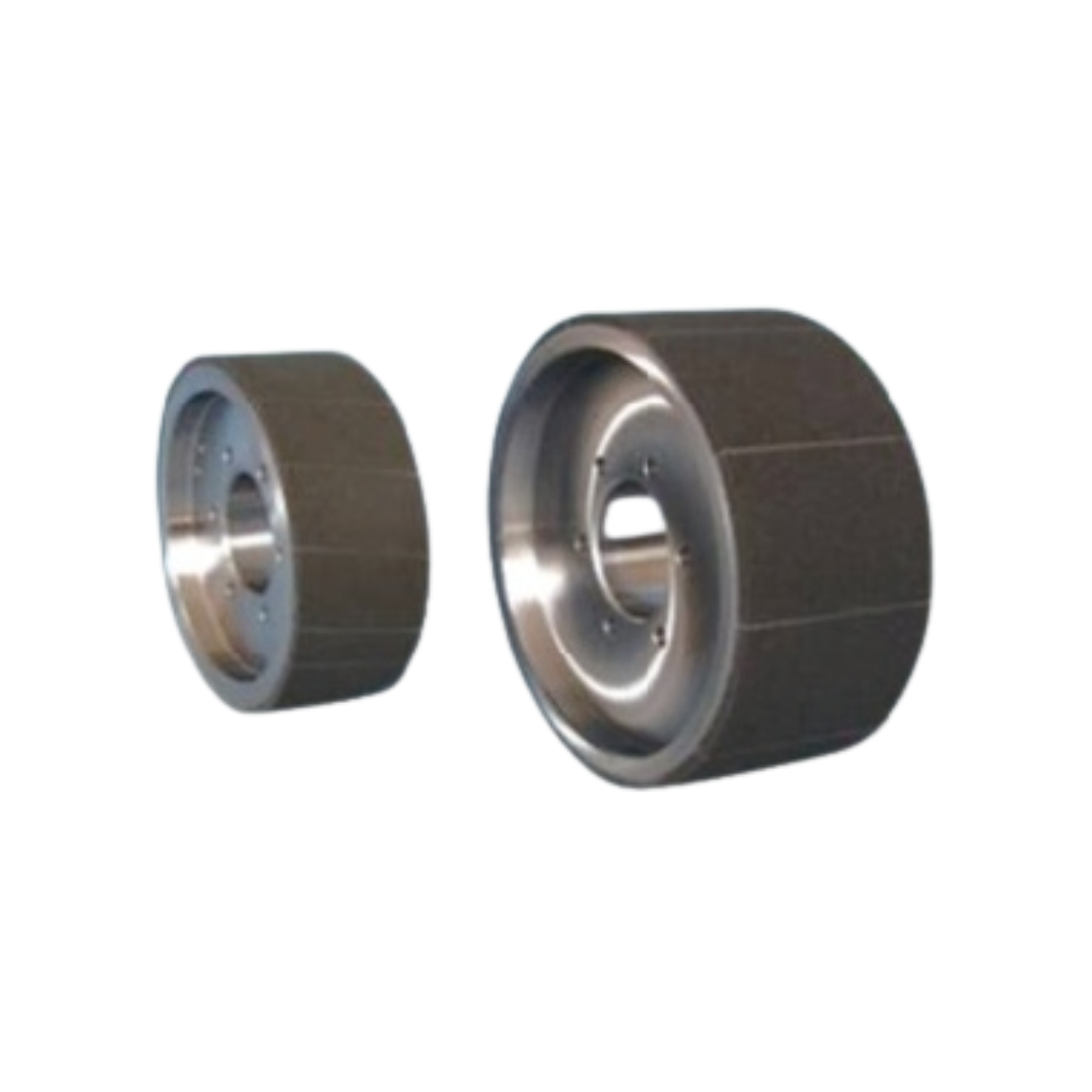

Electroplated Diamond and CBN Grinding Wheel

MAIN PURPOSE:

Electroplated diamond and CBN grinding wheels are primarily designed for precision grinding and cutting of extremely hard, brittle, or delicate materials where high accuracy, sharpness, and surface quality are critical.

TECHNICAL CHARACTERS:

- High-Precision Material Removal: Electroplated wheels have a single, uniform layer of abrasive particles (diamond or CBN) firmly bonded to the metal substrate via electroplating, providing sharp, consistent cutting edges that enable precise and efficient grinding or cutting of hard materials such as tungsten carbide, ceramics, glass, silicon wafers, composites, and hardened steels.

- Durability and Long Tool Life: The strong nickel or metallic bond formed during electroplating securely holds abrasive particles, allowing the tools to maintain sharpness and cutting efficiency over extended use, reducing the need for frequent dressing or replacement and thereby lowering downtime and costs.

- Free Cutting Action for Fast Cycle Times: The exposed abrasive particles protrude significantly from the wheel surface, enabling a free-cutting action that minimizes heat generation, reduces material deformation, and speeds up grinding cycles, which is especially beneficial in high-speed, high-precision manufacturing environments such as aerospace, automotive, electronics, and tool & die industries.

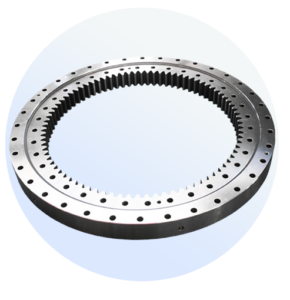

- Versatility Across Materials and Applications: Electroplated diamond wheels excel in grinding non-ferrous hard materials like carbides, glass, composites, and ceramics, while electroplated CBN wheels are ideal for grinding hardened steels and high-speed steels. These wheels are used for sharpening tools, shaping composites, slicing silicon wafers, and finishing delicate components without damaging microstructures.

- Reconditioning Capability: Unlike other bonded wheels, electroplated wheels can be stripped and replated with new abrasive layers, offering a cost-effective way to extend tool life and maintain performance over time.

Best Electroplated Diamond & CBN Grinding Wheel Supplier in India

Synergy Machine Tools is a trusted supplier of Electroplated Diamond and CBN Grinding Wheels in India, offering precision-engineered solutions for demanding grinding applications.

Known for sharp cutting action and superior profile retention, Synergy’s electroplated wheels are ideal for high-accuracy grinding of hard-to-machine materials such as carbide, ceramics, hardened steel, and superalloys. These wheels are particularly suited for contour grinding, tool and die manufacturing, aerospace, and medical applications where form stability and fast stock removal are critical.

Backed by strong technical expertise and a commitment to innovation, Synergy Machine Tools delivers high-performance electroplated grinding solutions that meet the precision and reliability standards of advanced manufacturing industries.

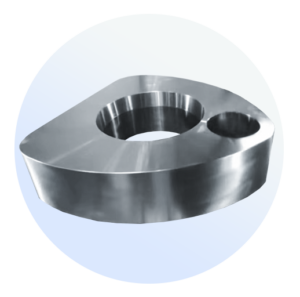

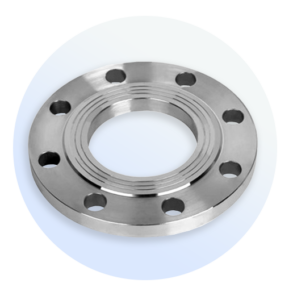

Components