SINGLE SURFACE LAPPING POLISHING MACHINE

Main Purpose:

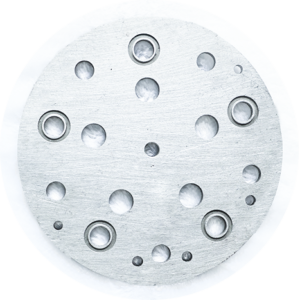

Single surface lapping and polishing machines are used for metal parts, such as valve plate, wearing plate, rigid seal ring, cylinder piston ring and oil pump blade, etc.as well as processing thin and hard brittle non-metal components of silicon, germa- nium, quartz, glass, ceramic, sapphire, gallium arsenide, ferrite, lithium niobate etc. such as mobile phone, LCD panel, Tablet pc.

TECHNICAL CHARACTERS:

- Water-cooled with three working stations.

- Equipped with peristaltic pump.

- This machine can exert pressure by weight and pressure plate’s dead weight which can judge the pressure.

- There is cooling water circulation system between the lapping plate and tray to ensure machine running reliable for a long time operation, and achieve the desired grinding (polishing ) effects.

- The machine at work through the editing processing procedure in the man-machine interface?and then downloaded to the PLC. PLC will be run by the current downloaded program

- PLC controlling, which it is flexible and reliable.

- Touch screen, it is convenient to show alert information and state. Besides, the interface is friendly and the information is huge.

- 24VDC of control components, PLC is supplied by isolation transformer, external electric wave interference is lowered, and the safety of the machine is greatly raised.

Specifications

| Project | Unit | YH2M8192 | YH2M8192|| | YH2M8195 | YH2M8164 | YH2M8164B (with trimming Mechanism) |

|---|---|---|---|---|---|---|

| Grinding disc size (outer diameter × thickness) | mm | φ914×35 | φ914×35 | – | – | – |

| Working ring size (outer diameter X inner diameter X height) | mm | φ410×φ368×60(3 pieces) | φ410×φ368×60(3 pieces) | φ400×φ375×60(4 pieces) | φ268×φ238×50(3 pieces) | φ268×φ238×50(3 pieces) |

| Maximum size of workpiece | mm | φ300 | φ300 | φ320 | φ220 | φ220(diagonal) |

| Highest flatness accuracy of abrasive parts /Highest flatness accuracy of polished parts | μm | – | – | 0.005(φ80)/0.008(φ80) | 0.003(φ80)/0.005(φ80) | – |

| Surface Roughness of Abrasive Parts / Surface Roughness of Polished Parts | μm | – | – | Ra0.15/Ra0.05 | Ra0.15/Ra0.125 | – |

| Grinding disc speed | rqm | 5~90 (stepless speed regulation) | 5~90 (stepless speed regulation) | 5~90 (stepless speed regulation) | 5~90 (stepless speed regulation) | 5~90 (stepless speed regulation) |

| Grinding disc motor | kW/ rpm | Power 7.5, rated speed 1450 | Power 7.5, rated speed 1450 | Power 11, rated speed 1450 | Power 7.5, rated speed 1450 | Power 5.5, rated speed 1450 |

| Cylinder (bore diameter × stroke) | piece | φ100×400 (3 pieces, weight pressurized) | φ80×450(3 pieces, weight pressurized) | φ80×450(4 pieces, weight pressurized) | φ63×550(3 pieces, weight pressurized) | φ63×600(3 pieces, weight pressurized) |

| Number of processing stations | piece | 3 | 3 | 4 | 3 | 3 |

| Dimensions (approximately: length x width x height) | mm | 1570×1725×2250 | 1600×1625×2150 | 1500×2200×2250 | 1225×1900×2350 | 1550×1700×2250 |

| Total Weight | kg | 2000 | 2500 | 2800 | 2100 | 1900 |

PROCESSING WORKPIECE

The device can be processed workpiece, including glass, ceramic pieces, sapphire, bearings, valves, carbide inserts, seals, oil pump blades, piston rings, such as: