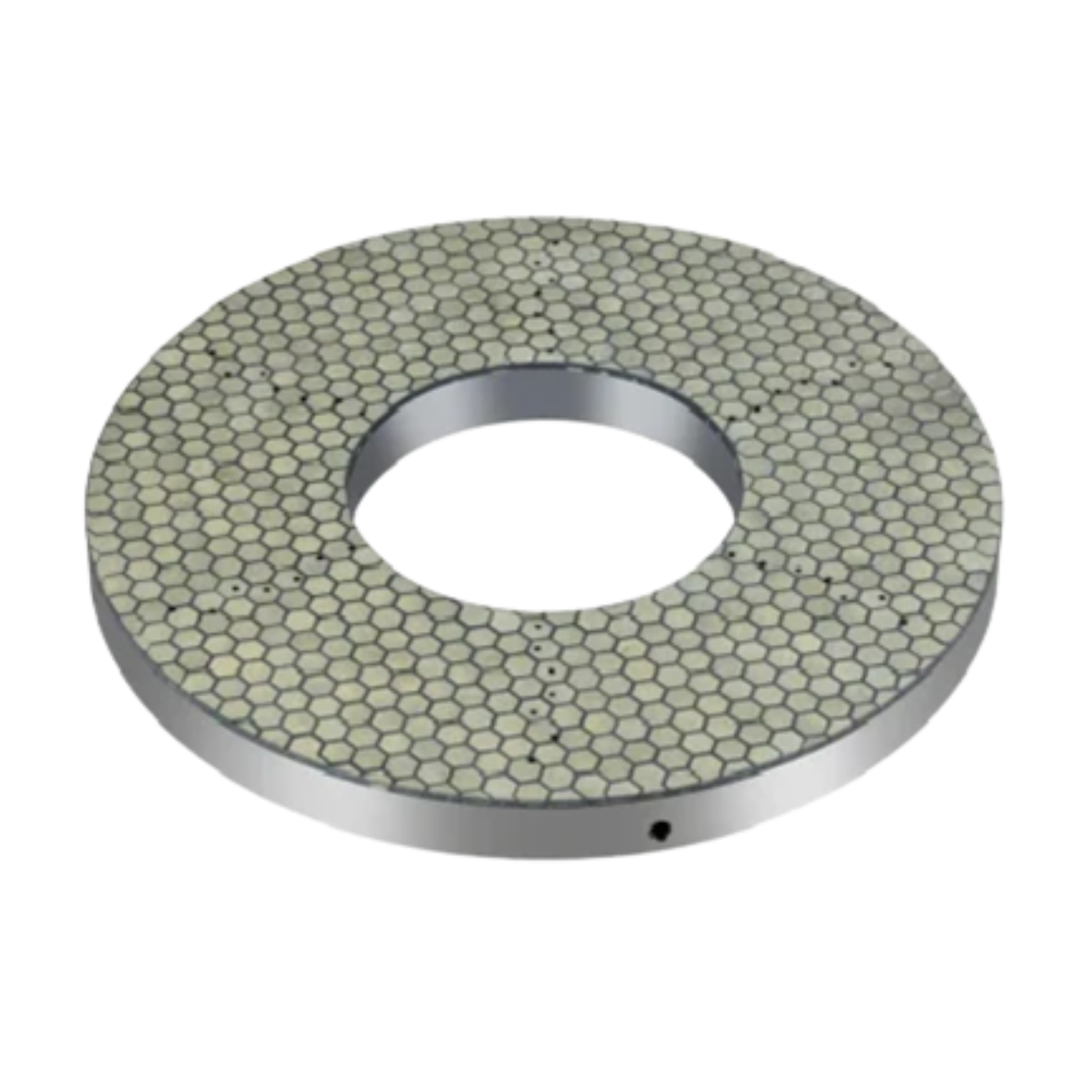

Vitrified Double Disc CBN Grinding Wheels

MAIN PURPOSE:

The main purpose of Vitrified Double Disc CBN (Cubic Boron Nitride) Grinding Wheels is to achieve high-precision, high-efficiency surface grinding on hard ferrous materials (like hardened steel, tool steel, cast iron, and superalloys), particularly in double disc grinding machines where parallelism and flatness are critical.

TECHNICAL CHARACTERS:

- Simultaneous Double-Sided Grinding: These wheels are used in double disc grinding machines to grind both sides of a workpiece at once, ensuring high levels of flatness and parallelism on opposing surfaces, which is critical for components requiring tight tolerances.

- High Production Efficiency: The vitrified bond structure allows for aggressive material removal rates while maintaining excellent surface quality and dimensional accuracy, making them ideal for mass production environments such as automotive, bearing, and aerospace industries.

- Superior Wheel Life and Cost-Effectiveness: CBN is extremely hard and durable, offering 100–300 times the lifespan of conventional abrasive wheels. This reduces downtime for wheel changes and lowers overall grinding costs despite higher initial investment.

- Reduced Thermal Damage: The high thermal conductivity of CBN, combined with the porous vitrified bond, efficiently dissipates heat away from the workpiece. This minimizes thermal damage and preserves the integrity of heat-sensitive materials.

- Consistent Surface Finish and Precision: These wheels deliver high surface quality, flatness, and parallelism, with roughness values as low as Ra 0.02–0.2 µm and flatness/parallelism within 2 µm, making them suitable for demanding applications such as mechanical seals, hydraulic components, and compressor parts.

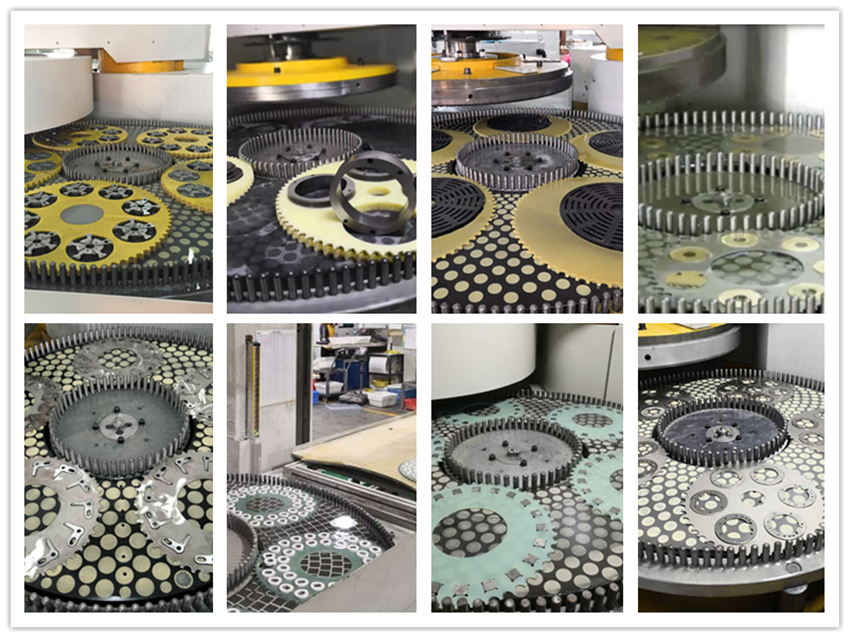

FINE GRINDING PROCESS

High precision surface grinding or fine grinding is a super finishing process performed by removing material from two surfaces of a component resulting in extremely precise geometric accuracy and surface finish. Typically, it is the last grinding step of a mechanical production chain utilized to improve and/or correct the geometry of parts coming from sintering, sawing, molding or similar operations. Depending on the application, the stock removal also can be taken from just one surface.

When the machine is working, upper and lower grinding discs as well as the planet wheel rotate simultaneously to drive work pieces to do reciprocating planet motion between the two grinding plates. Various grinding materials such as super hard abrasive: Diamond grinding plates, CBN(cubic boron nitride) grinding plates; Conventional abrasives: Cast iron plates, GC plates, etc can be adopted for different requirements of various products, so as to achieve double side precision grinding on work pieces made from various materials. Our equipment take advanced probe side measurement and Sony size measuring controller to realize real-time online measurement control on processed work pieces.

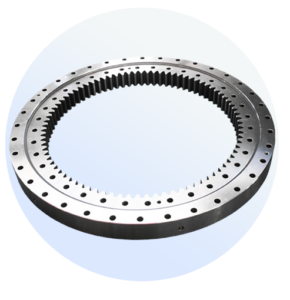

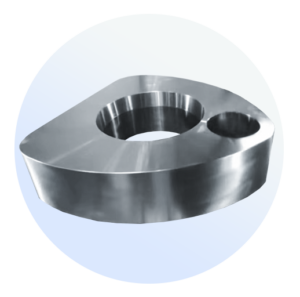

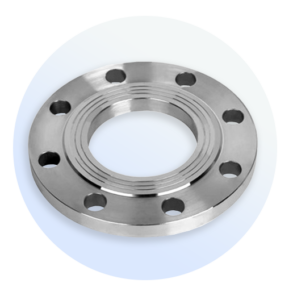

COMPONENTS DURING FINE GRINDING PROCESS

Best Vitrified Double Disc CBN Grinding Wheels Supplier in India

Synergy Machine Tools is emerging as one of the best suppliers of Vitrified Double Disc CBN Grinding Wheels in India, known for delivering high-precision and performance-driven grinding solutions. With a strong focus on innovation and quality, Synergy collaborates with global technology leaders to offer advanced CBN grinding solutions ideal for high-speed, high-accuracy applications in the automotive, aerospace, bearing, and tooling industries. Our vitrified CBN wheels are engineered for double disc grinding machines, providing excellent dimensional control, surface finish, and extended wheel life. Backed by a team of technical experts and a customer-centric approach, Synergy Machine Tools stands out as a reliable partner for industries seeking consistent quality and productivity in grinding operations.

Components