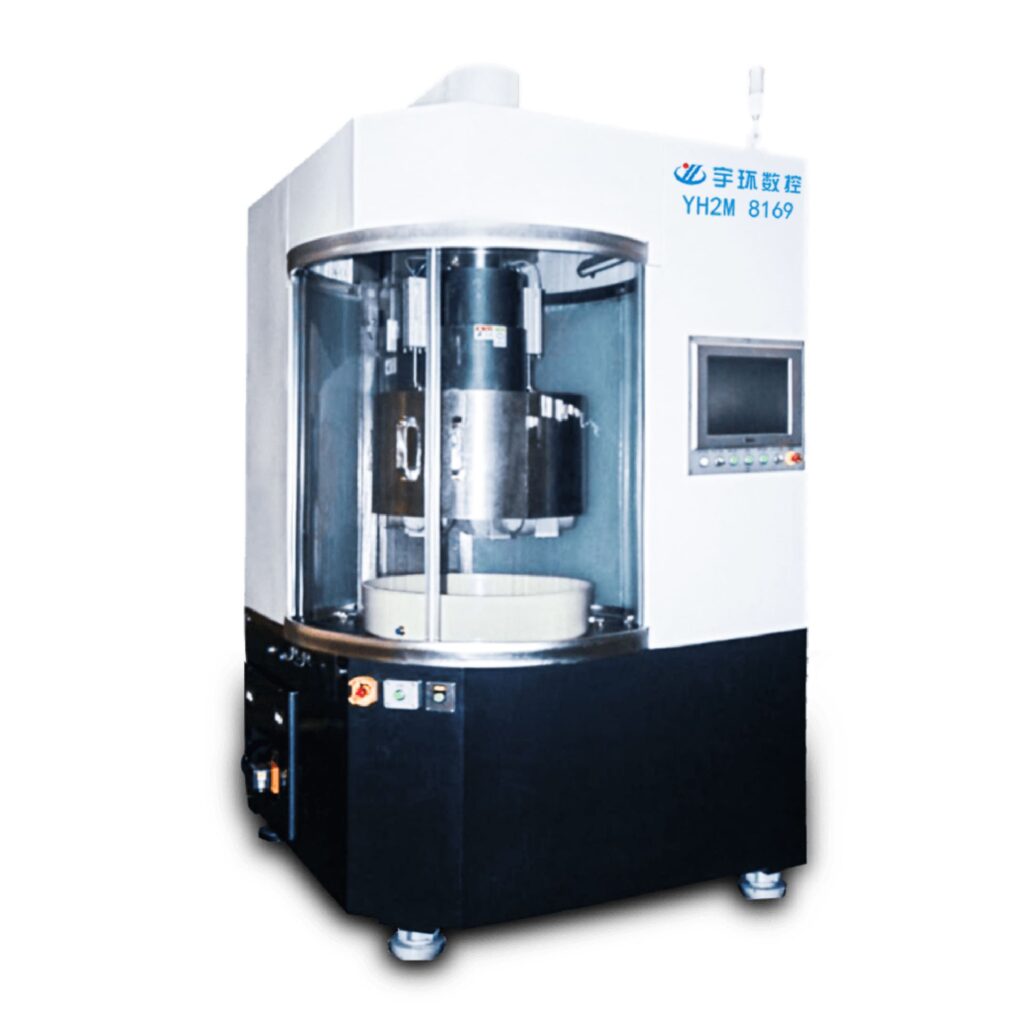

3D MAGNETIC FLOW POLISHING MACHINE

MAIN PURPOSE:

This machine is mainly used for 3D precision polishing of non-magnetic materials such as aluminum-magnesium alloys, glass, sapphire, and stainless steel.

TECHNICAL CHARACTERS:

- This machine is a magnetorheological polishing machine that uses magnetorheological fluid to polish the workpiece by means of electromagnetic field magnetization.

- The workpiece is clamped on the manipulator with 6 double degrees of freedom on the revolving plate.

- The magnetic field of this machine adopts low-voltage magnetic field, with high safety, and the magnetic induction intensity can be programmed.

- The machine’s magnetic field and polishing liquid temperature are controlled by a special cooling system.

- The control mode of this machine is PLC+touch screen mode.

SPECIFICATION

| Project | Unit | Parameter |

|---|---|---|

| Number of stations | indivual | 6 |

| Maximum size of workpiece | mm | 165(diagonal)x40(height) |

| Polishing basin size | mm | φ630 |

| Upper plate speed | rpm | 3-85 |

| Workpiece speed | rpm | 3-62 |

| Robot swing angle | – | -5°-12° |

| Upper plate motor power | kW | 3 |

| Robot swing motor power | kW | 0.4 |

| Manipulator rotation motor power | kW | 0.1 |

| Switchboard size (LxWxH) | mm | 1800x2800x2600 |

| Switchboard weight | kg | 2800 |

PROCESSING WORKPIECE

The device can be processed workpiece, including glass, ceramic pieces, sapphire, bearings, valves, carbide inserts, seals, oil pump blades, piston rings, such as: