YHDM580B/3 HIGH PRECISION DOUBLE DISC GRINDING MACHINE

MAIN PURPOSE:

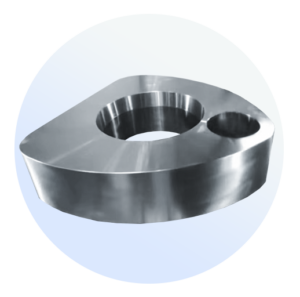

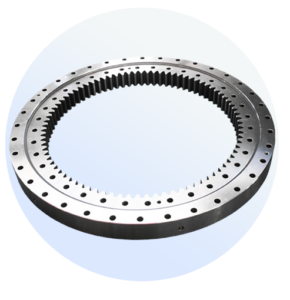

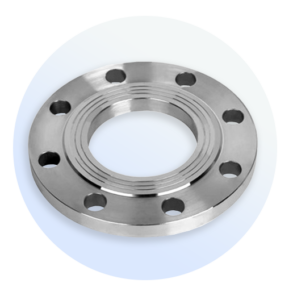

It can process and grind double ending-surface for non-metal parts(glass,

ceramics etc) which are featured by hard, brittle, thin in high-efficiency and precision, also precisely grind two up & low parallel surfaces for metal thin precision parts(bearing, valve plate, seal, oil pump vane, piston ring etc).

TECHNICAL CHARACTERS:

- The Machine adopts a casting box-shaped structure, which has good shock absorption, good

- Machine designed to adopts diamond wheel / CBN wheel for high-efficiency and high-quality grinding.

- al stability.

- Adopts Siemens 808D CNC system, More optimized HMI.

- Adopting a hinged Carrier feeding mechanism, it can be opened flexibly, and it is convenient to replace and dress the grinding wheel.

- Equipped with automatic grinding wheel dressing device, which is convenient and quick to ensure the grinding wheel dressing quality.

- Except for the Heavy Duty spindle motor controlled thru Variable Freequency drive to optimised the grinding efficiency.

- All the Axis driven by servo motors, with stable movement, accurate positioning and easy adjustment.

- Wheel head feeding adopts high-precision ball screw,feeding precision:0.001mm.

- Feeding carrier mechanism adopts servo-motor,stable drive,realize 1~10 r/min stepless speed control.

- The cooling liquid is magnetically separated, filtered with paper tape 2-stage filtration, and recycled after the temperature of the cooler is controlled.

SPECIFICATION

| Item/Product Model | Unit | YHDM580B/3 |

|---|---|---|

| Workpiece diameter | mm | Φ20-Φ320 |

| Workpiece thickness | mm | 8-40 |

| Wheel size | mm | Φ585xΦ195 |

| Grinding head motor | kw | 30×2 |

| Grinding head speed | rmp | 50-950 |

| Feeding tray motor power | kw | 1.5 |

| Machine quality | kg | 9000 |

| Machine tool dimensions (length x width x height (LxWxH) | mm | 2550x2300x2880 |

PROCESSING METHODS

Oscillating grinding (BD)

Suitable for thick workpieces, workpieces with verticality requirements, large removal amount

PROCESSING WORKPIECE

The device can be processed workpiece, including glass, ceramic pieces, sapphire, bearings, valves, carbide inserts, seals, oil pump blades, piston rings, such as: